Coaxial solenoid and air pilot 2 and 3 way valves

Coaxial valves 2/2 way (2 ports 2 positions) or 3/2 way (3 ports 2 positions) with Solenoid control or Pneumatic external control air pilot via Namur interface.

Port sizes from 1/8 up to 2 thread or flange for pressures from vacuum up to 300 Bar.

Manufactured in Brass, Steel, Aluminium, 304 or 316 Stainless steel with a range of sealing materials to suit every application such as Viton, EPDM, NBR, UHMW Polyethylene and PTFE to name but a few.

The coaxial valve design offers fast, effective bidirectional sealing and very high flow rates with relatively unobstructed flow path offering minimal pressure loss.

Coaxial valves are suitable for most fluids and gases, even thick viscous liquids up to 1,000 centistokes (square mm per second), corrosive acids and alkalis and abrasive ceramic pastes and vacuum to name but a few.

Do you need a Coaxial Valve for your application?

System requires high flow rates with minimal pressure loss?

Media being controlled is more than 50 centistokes (Thick), contaminated or abrasive?

System has a high back pressure?

System flow in both directions?

System requires extremely fast acting valves?

You have a vacuum system?

Very low or zero pressure differential? (inlet and outlet pressures can equalise)

For oxygen service up to 20 or 40 Bar +60C Max, with special sealing and oxygen cleaning?

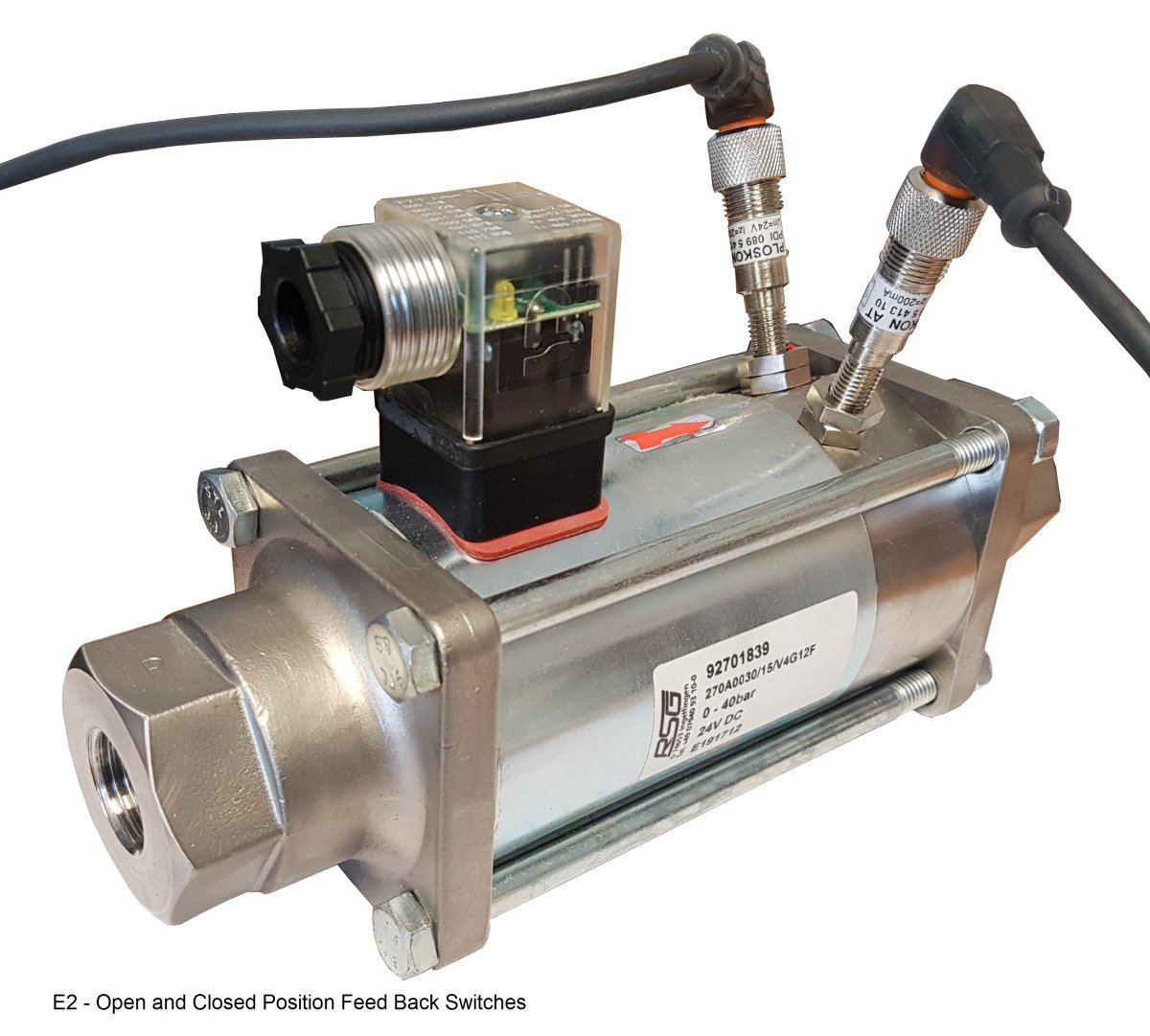

Require position feed back for open and or closed position?

Require a manual override facility?

Require mounting brackets?

Require a robust maintenance free valve with high cycle life for:

Ceramic pastes

Oils, corn oil, olive oil, castor oil, coconut oil, sesame seed oil, palm oil, linseed oil, etc

Creams, sour cream, ice cream, skin cream

Butter, peanut butter, almond butter, hazelnut butter, margarine etc.

Liquid Fats

Syrup or honey

Ink

Molten chocolate

Sauce

Thick hydrocarbons

If you require any or all of the above, you can view and buy a full range of coaxial valves here.

What is a coaxial valve?

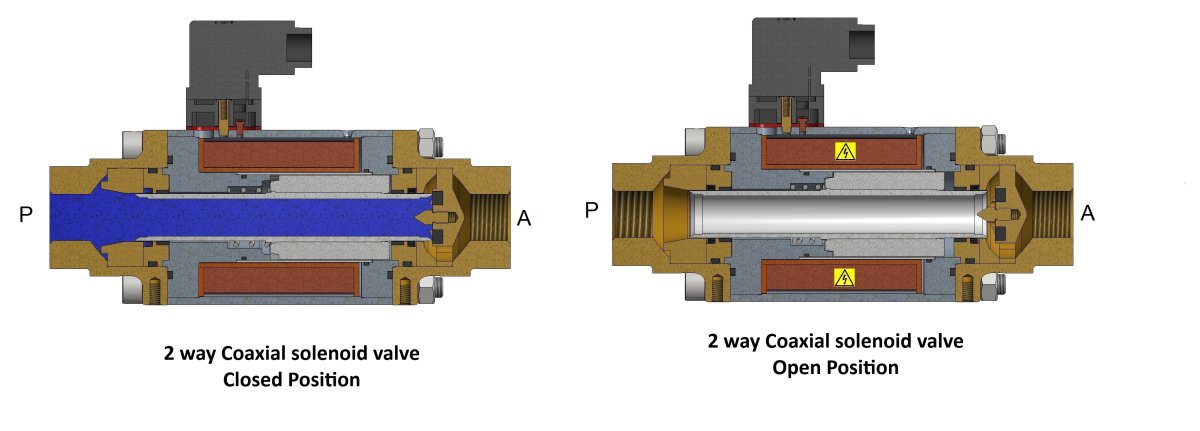

A coaxial valve is an electromechanically or pneumatically controlled valve. A coaxial valve is controlled by either an electric current through a solenoid or by pneumatic (pressurised gas) to produce a mechanical function. In the case of a two port coaxial valve the flow is switched on or off, in the case of a three port coaxial valve, the out flow is switched between two outlet ports. Multiple coaxial valves can be placed together on a manifold.

Coaxial valves are most commonly used to control liquids and gases, whose task is to shut off, release, dose, distribute or mix gas or liquid media. Coaxial valves offer fast and safe reliable switching, very high liability, excellent medium compatibility of the materials of construction, low power or air consumption, compact and high flow design for many vacuum, inert, aggressive, contaminated and glutinous liquids.

The coaxial valve design allows for vastly improved linear straight-line flow along a tube and does not suffer the same restrictions normally found with a general-purpose solenoid valve. Coaxial valve construction consists of a laterally mounted tube usually mounted in a Brass or Stainless Steel housing allowing for lateral tube movement from (to open allowing media flow) or against (to close preventing media flow) a range of static elastomer rubber or PTFE seals.

Operation.

There are two main valve design variations. Ordinary coaxial valves can have many ports and fluid paths. A 2-way valve for example, has 2 ports; if the valve is closed, then the 2 ports are isolated media cannot flow; however if the valve is open the media may flow between the ports. If the coaxial valve is closed when not actuated (either energised to solenoid or pressurised if pneumatically operated), then the coaxial valve is termed normally closed. Similarly if the valve is open when not actuated the valve is termed normally open. There are also 3-way and manifold design options also found. A 3-way coaxial valve has 3 ports; it connects one port to either of the other two ports (typically a supply port to an exhaust or diverting port).

Coaxial valves are all characterised as direct acting, in both solenoid and externally piloted (external gas or air supply) as the controlling mechanical function is direct linked to the open and close function of the valve and does not reply on any system pressure to before this function. Thus a coaxial valve can work from vacuum to pressures exceeding 200 bar (2942 psi or pounds per square inch) and with PTFE seals can withstand temperatures up to 200 degrees centigrade.

Port Sizes.

Coaxial valves are usually available in a range of port sizes typically in threaded BSP or NPT from 1/8" thread to over 2" thread or with a range of flange options. The port size generally does not affect the flow rate unless the port is smaller than the internal tube diameter sometimes referred to as the orifice size.

Orifice and Flow Rates.

There are a range of internal tube diameter sizes available for coaxial valves (both solenoid and pneumatically operated) typically 10mm internal diameter to 50mm. The tube internal diameter typically determines the flow rate (excepting that the port size is of equal size or more) offering a specific flow coefficient according to tube diameter. For example in the case of a 2-way coaxial valve typical Kv flow coefficients in litres per minute would be:

Tube Diameter (mm) |

Flow (Litres per minute) |

10 |

51 |

15 |

91 |

20 |

145 |

25 |

205 |

32 |

333 |

40 |

637 |

50 |

787 |

In practical terms Kv flow coefficient is the amount of water at 20°C that would flow with a pressure drop of 1 kilogram per centimetre across the valve. i.e. the pressure difference between inlet and out let pressure).

Coaxial valve are available in 2/2 way (2 ports inlet and outlet) and 2 positions (fail safe open or fail safe closed) and 3/2 way (3 ports for example 1 inlet and 2 outlets for diverting flow) with 2 positions (fail safe open or fail safe closed against the second of third port). Due to the compact nature of coaxial valves they can easily be mounted onto a manifold system with either common inlet or outlet.

Materials.

The valve body must be compatible with the media; common materials are steel, brass, AISI304 or AISI316 stainless steel.

The seals must also be compatible with the fluid.

To simplify the sealing issues, the valve body and tube are exposed to the media, so they must be compatible as well. The requirement presents some special but easily resolvable problems. The internal tube is typically 316 stainless steel which has a good chemical resistance, however the valve body will so need to be compatible material. The surrounding mechanical parts attached to the tube required for operation and the springs are sealed and are not exposed to the media.

Types.

Many variations are possible from the basic 2/2 way (2 ports (inlet/outlet and 2 positions open/closed)

The coaxial valve tube position can be mechanically checked by installing a position switch into the body which can be activated by the lateral movement of the internal tube to confirm the coaxial valve open and or closed position for remote signal confirmation by an operator.

The coaxial valve tube can also be mechanically moved laterally by a simple addition of a mechanical lever or cam thus providing a manual over ride facility for engineers during installation or power failures.

View all 2/2 coaxial solenoid valves.

View all 2/2 coaxial pneumatic valves

View all 3/2 Coaxial solenoid valves

View all 3/2 Coaxial pneumatic valves

Coaxial Modular Systems

Coaxial Valve Technology “

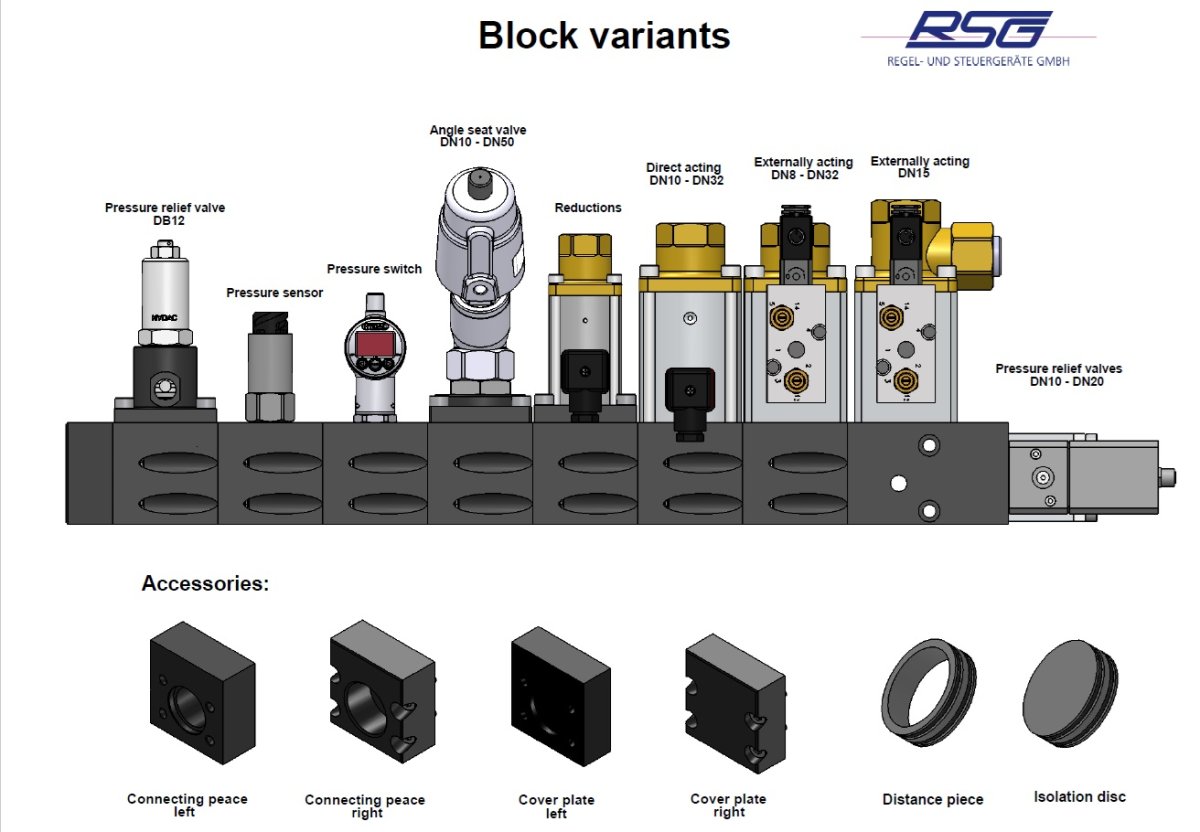

Leading the way forward. Connexion Developments Ltd, in collaboration with RSG Regel - und Steuergerate GmbH, is pleased to announce a significant achievement in the realm of custom manifold design, specifically in the coaxial valve domain.

Initially employing standard 2/2 way coaxial valves for the construction of high-pressure 40 Bar fluid control systems, our client sought a more tailored solution for their manifold system.

Recognizing the limitations of the existing approach, we introduced the RSG 270X modular system, which proved to be an optimal choice.

This modular system offers versatility through a range of combinations and full customization capabilities, accommodating pressure control valves and monitoring devices. The seamless integration of the RSG 270X modular system paved the way for the development of a fully customized 3D-printed plastic valve manifold system tailored to the client's specifications. This bespoke solution, meticulously crafted to meet both dimensional and functional requirements, was delivered within a commendable 30-day timeframe in September 2022.

Following rigorous functional tests and evaluations, the successful validation in May 2023 led to the awarding of an 18-month contract. In July, a minor, non-critical modification to the valve's exterior was seamlessly incorporated into the design.

Despite this modification, the delivery timeline only experienced a minimal extension of three weeks. Consequently, the complete delivery was expedited, and the project was successfully concluded in early November 2023.